KWH Freeze 60 years

From Fur Feed to Ice Cream – The Journey of KWH Freeze

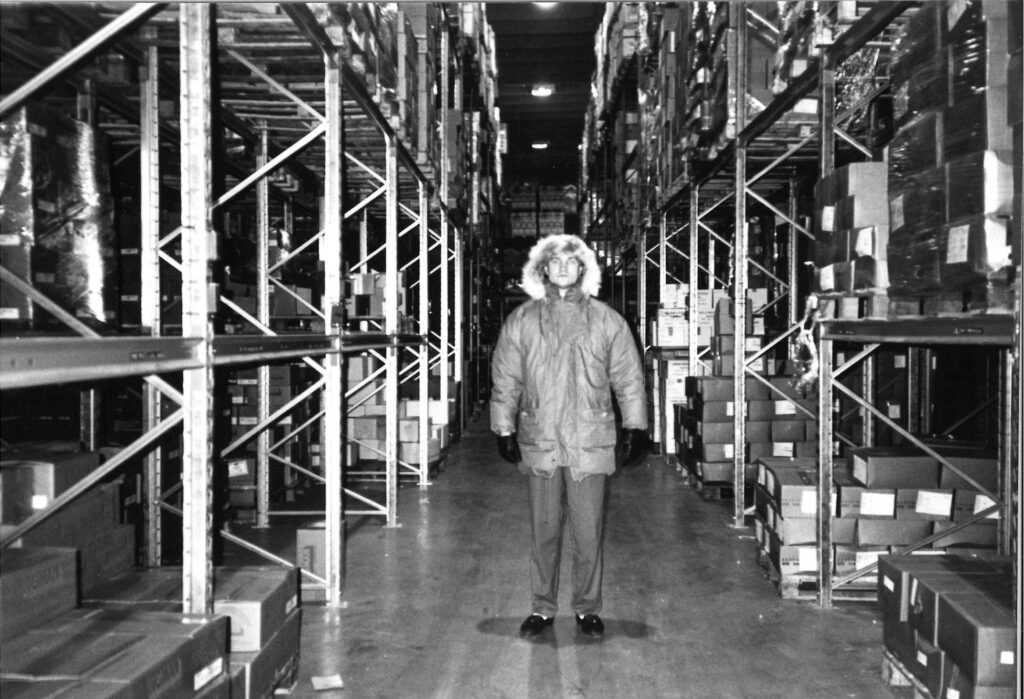

The history of Freeze is closely linked to Oy Keppo Ab, which in the 1960s was the world’s largest fur producer, based in Ostrobothnia. Etelän Jää – Söder Is, the predecessor of KWH Freeze, was founded on February 12, 1965 to provide frozen storage for the fur feed required in Keppo’s fur production. The feed was made from herring and fish waste, making a reliable cold chain essential.

Later, in the 1980s, fur production was discontinued, and Keppo merged with Wiik & Höglund, forming the structure of what is now KWH Group. KWH Group acquired KWH Freeze in 1986, and in 2001, Freeze became part of the KWH Logistics business group within KWH Group. KWH Freeze grew so rapidly that it was separated into its own business group in 2021.

In 2025, after 60 years of operation, KWH Freeze stands as Finland’s leading provider of frozen storage.

Investments and Quality – The Recipe for Strong Growth

KWH Freeze has always been a bold investor, playing a key role in enabling rapid growth. Between 2018 and 2022 alone, the company’s storage capacity increased by 20%, and expansion continues. In addition to substantial capacity, Freeze has always prioritized quality. KWH Freeze was one of the first Finnish companies in the industry to receive the FSSC 22000 certification, ensuring high-level expertise in food safety. Further demonstrating its commitment to quality, the company also holds ISO 9001, ISO 14001, and ISO 45001 certifications.

We are also actively working towards NIS2 and ISO 27001 certifications to enhance our data security and cybersecurity.

KWH Freeze has always been a bold investor, playing a key role in enabling rapid growth. Between 2018 and 2022 alone, the company’s storage capacity grew by 20%.

Technology and Automation Enhance Operations

Digitalization has also been taken as far as possible and is continuously developed in collaboration with customers. Customers’ IT systems are integrated with KWH Freeze’s IT systems, enabling fast and automatic deliveries as well as real-time inventory updates. In addition, automation and artificial intelligence in the warehouse reduce manual labor and streamline processes. Digital tools are also used for staff training, meaning technology is deeply integrated into the core of Freeze’s operations.

Towards Carbon-Neutral Operations

Energy issues and sustainability have always been important to Freeze. A major leap in energy efficiency was made in 2020 when the roof area of the freezer warehouse was harnessed for solar energy. “From a sustainable development perspective, a major challenge for KWH Freeze has been our energy use and how we can utilize the waste heat generated in our cooling process. We have been looking for a solution to this issue for almost 15 years, and now we are close to finding one,” says Peter Lång, Business Group Director and CEO of KWH Freeze. The solution will be realized when the waste heat from KWH Freeze’s freezer warehouse is used to heat homes and commercial buildings through the district heating network in Vantaa.

Skilled and Satisfied Staff – The Key to Success

However, the most important resource is the people. Without skilled and motivated employees, there would be no operation. Employee well-being is a priority, and success in this area is evident: long careers, positive feedback from staff, and Freeze is also an attractive employer for new job seekers.

Thank you to all our employees and everyone who has worked with us over the years – each of you is a part of our 60-year history!